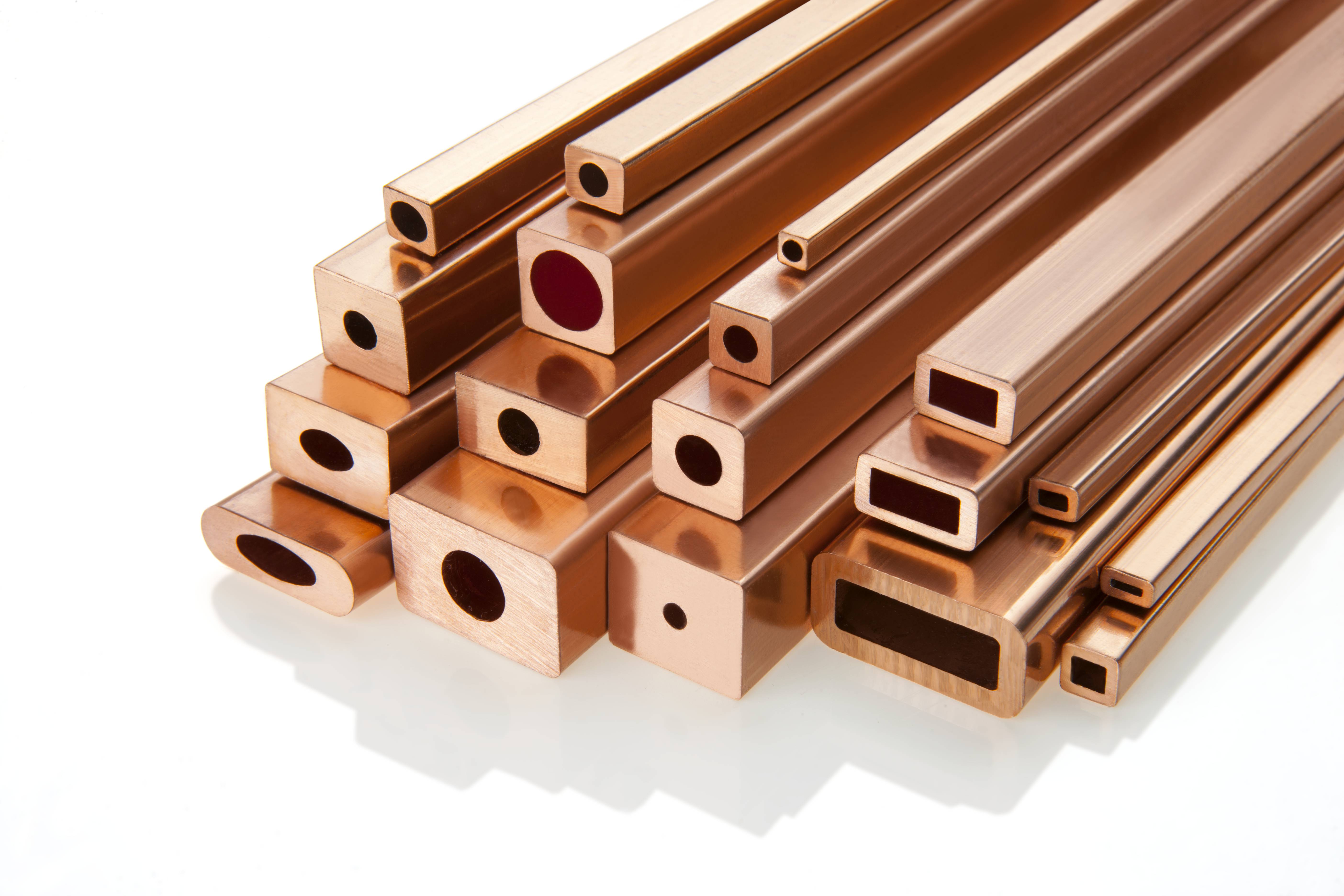

High Quality Hollow Conductors for Induction Furnaces

Hollow conductor is the heart of a coil, and the coil is the heart of an induction furnace. With the new hot extrusion press, Luvata Pori has more capabilities to serve customers with custom requirements and higher quality, such as those involved in producing induction heating and melting systems.

Compared to most other ways of melting metal, induction furnaces are widely used due to their energy efficiency in melting or holding molten metal. The melting process starts when an AC current is supplied to the copper coil, creating an electromagnetic field which couples with the electrically conductive material in the furnace. This results in joule heating of the metal to be heated.

“Frequency in the coil can vary from 50 Hz to greater than 10 kHz with currents in some designs flowing in excess of 15,000 amps in the coil conductors. It generates a lot of heat so it must be cooled down, otherwise it couldn’t last even five minutes”, explains Luvata Pori’s Product Group Manager Henri Koivumäki.

Luvata Pori is an experienced manufacturer of hollow conductors and has excelled in this field for over five decades. Luvata’s products are widely used in induction solutions due to their ability to facilitate cooling. Hollow conductors are the best choice for material to be used in a coil because their shape, dimensions and wall thickness can be customized according to requirements and because cooling water can flow inside the coil

Enhanced Capacity with the New Hot Extrusion Press

With the new hot extrusion press and its fully automated operations, Luvata can serve its customers better with increased capacity and power. One of the pleased customers of Luvata Pori’s extruded products is US based Ajax Tocco, which is a manufacturer of innovative induction heating and melting systems. Coils in their induction furnaces require large hollow conductors that are manufactured with the hot extrusion press.

“Design of the coil depends on several things including applied current density, furnace capacity, material to be melted, used frequency, coil conductor water flow capability, and conductor shape for structural integrity. This is why a coil in one induction furnace can have a different size and shaped hollow conductor than other ones”, states David A. Lazor, Technical Director from Ajax Tocco.

“I am happy with the product range that Luvata can offer. If the right tool is not directly available, they can design, and manufacture hollow conductors based on our requirements. This supports us to offer innovative and efficient solutions to our customers”, continues Lazor.

Get to know Luvata’s Hollow Conductors better.

Contact our Product Expert

Henri Koivumäki

+358 40 847 4385

henri.koivumaki@luvata.com